Phenol-formaldehyde Resin For Producing Manufactured Wood

Phenol-formaldehyde Resin For Producing Manufactured Wood has advantages such as water resistance and low formaldehyde emission levels. For example, certain construction formwork plywood that produced with super E0 Phenol-formaldehyde Resin was required.

Phenol-formaldehyde Resin For Producing Manufactured Wood

The advantages of phenolic resin adhesive in the manufacture of sheet materials include:

1. Strength and stability: Phenolic resin adhesive can provide high-strength bonding, making sheet materials more robust and stable.

2. Water resistance: It has excellent water resistance, making it less susceptible to moisture, which is crucial for sheet materials used in humid environments.

3. Heat resistance: Phenolic resin adhesive can withstand high temperatures, maintaining the stability of sheet materials under high-temperature conditions.

4. Chemical resistance: It exhibits good resistance to certain chemicals, making it less susceptible to chemical corrosion.

5. Dimensional stability: Phenolic resin adhesive can maintain the dimensional stability of sheet materials, preventing them from expanding or contracting.

6. Wear resistance: It can enhance the wear resistance of sheet materials, extending their lifespan.

7. Bonding speed: Phenolic resin adhesive typically cures in a relatively short time, increasing production efficiency.

8. Low formaldehyde emission levels: Phenol-formaldehyde adhesive in the manufacturing of MDF boards typically has low formaldehyde emission levels. This is because the chemical properties of phenol-formaldehyde adhesive result in relatively low formaldehyde emissions after curing.

These characteristics make phenolic resin adhesive an ideal choice for the manufacture of various sheet materials such as plywood, medium-density fiberboard (MDF), particleboard, and more. They can provide high-quality, strong, and stable sheet materials suitable for applications in construction, furniture manufacturing, shipbuilding, and various other industries.

In the woodworking space, phenol formaldehyde is sometimes used in the manufacturing of medium-density fiberboard and particleboard. Those materials find application in furniture making, cabinetry, and flooring products. The function of the resin is to create a strong and durable bond between the wood fibers.

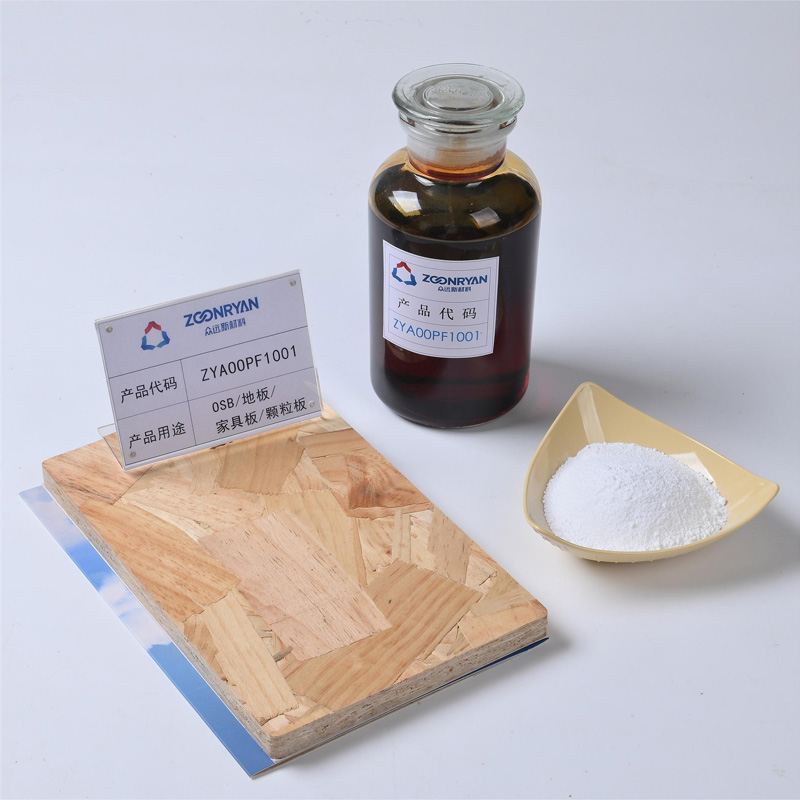

Phenol-formaldehyde (PF) resin is a common resin used in the wood industry. It's used to make plywood, oriented strand board (OSB), particle board, and medium-density fiberboard (MDF). PF resin is also used in the manufacture of composite wood panels and wood-based panels.

Manufactured Wood phenolic aldehyde resin is a key component in the production of manufactured wood, such as plywood and particleboard. It contributes to the strength and durability of manufactured wood in several ways:

Adhesive properties: Phenol-formaldehyde Resin Powder acts as a powerful adhesive, bonding the wood particles or veneers together. This adhesive property helps to create a strong and stable structure.

Water resistance: Phenol-formaldehyde resin has excellent water-resistant properties. It helps protect the wood from moisture, reducing the risk of swelling, warping, and decay. This makes the manufactured wood more durable and suitable for various applications, including outdoor use.

Chemical stability: Phenol-formaldehyde Resin Powder is highly resistant to chemical degradation. It can withstand exposure to acids, alkalis, and solvents, making the manufactured wood more resistant to chemical damage.

Heat resistance: Phenol-formaldehyde resin has good heat resistance, allowing the manufactured wood to withstand high temperatures without losing its structural integrity. This property makes it suitable for applications where heat resistance is essential, such as in the construction of fire-resistant doors.

Overall, phenol-formaldehyde resin enhances the strength, durability, and performance of manufactured wood by providing excellent adhesion, water resistance, chemical stability, and heat resistance.