Phenol Formaldehyde Resin Powder 98% Purity

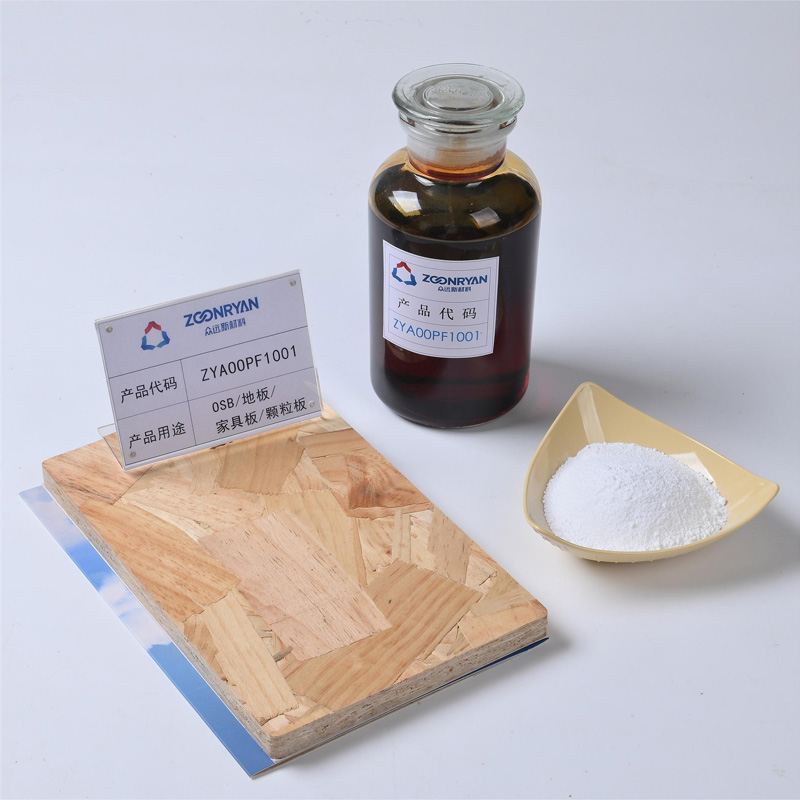

The phenol-formaldehyde resin is a thermosetting adhesive. phenol formaldehyde 98% Purity is suitable for the production of plywood made from various hard or soft woods, including OSB, LSB, particleboard, fiberboard, construction templates, and flooring substrates.

ZYA00PF1001 is a liquid phenol-formaldehyde resin adhesive developed by Shandong Zoonryan New Materials Co., Ltd., designed to meet Class I bonding strength and Class I immersion peel performance requirements. This adhesive is derived from phenol and formaldehyde and has been modified to have extremely low levels of free phenol and free formaldehyde, while retaining very high bonding strength, excellent water resistance, and weather resistance. In practice, this adhesive has demonstrated high bonding strength, excellent water resistance, and good weather resistance. Testing of phenol formaldehyde powder parameters reveals that the free formaldehyde content is ≤0.005%, free phenol is ≤0.03%. Plywood produced with this adhesive meets the bonding strength and immersion peel performance requirements of national Class I boards. The formaldehyde emission from the plywood is ≤0.025mg/m³.

Phenol formaldehyde resin powder is a type of thermosetting resin that is produced by the reaction of phenol with formaldehyde. It is commonly used as a binder or adhesive in various industries, including woodworking, construction, and electrical insulation.

Test Report

Number:XX2023042452

About Us Sample Name | MIP Faced Plywood | Sample Grade | Qualified | ||||

Qualities | 500mm*500mm for two | Specifications | 1220*2440*18 | ||||

Production date | 202/06/ 29 | Test Date | 2023 /07/12 | ||||

Inspection | GB/T 17657 -2013 | ||||||

Determination | GB/T 39600 -2021 GB/T 34722 -2017 | ||||||

No. | Items | Technical requirements | Test Result | Judgment | |||

1 | Formaldehyde release | Enf ≤0.025 | 0.011 | Qualified | |||

2 | Moisture | 6.0%~16.0% | 7.1% | Qualified | |||

3 |

Impregnation delamination |

/ |

No Delamination |

Qualified | |||

4 | Lateral static bending strength | Average ≥15.0MPa Lowest ≥12.0MPa | Average/23.2MPa Lowest/16.8MPa |

Qualified | |||

5 | Bonding Strength | ≥0.60MPa | 1.10MPa | Qualified | |||

6 | Surface crack resistance | Above 4th level | 5 level | Qualified | |||

Specification

Phenol formaldehyde resin powder with 98% purity has the following properties:

Excellent ablative properties

Good flame resistance

Smoke properties

Easy to mold

Retains properties at freezing temperatures