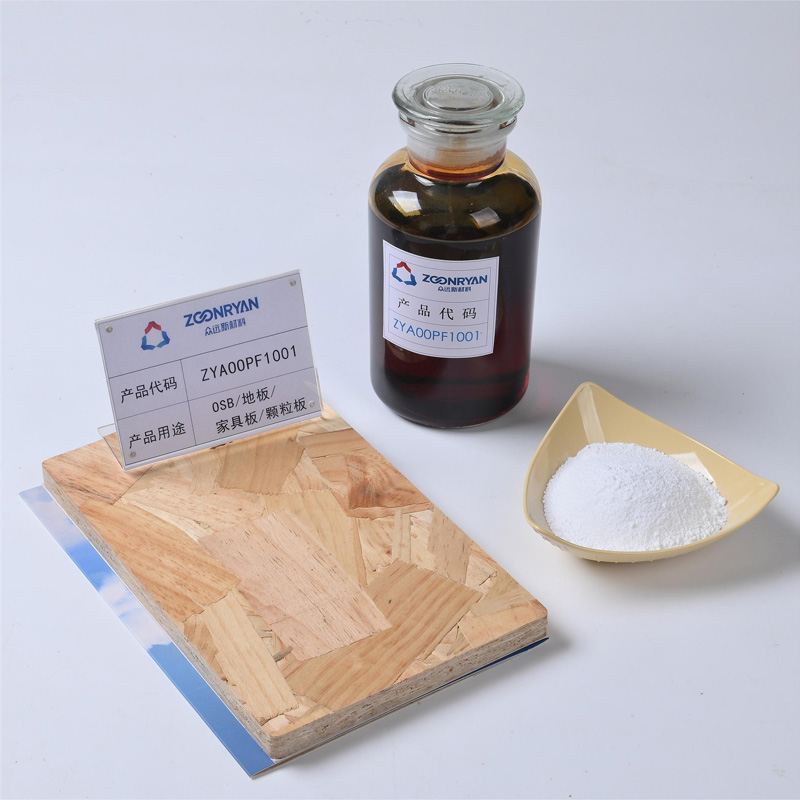

Phenol-formaldehyde Resin For Producing Particle Board

Over time, Zoonryan New Materials has developing new manufacturing technologies for phenol-formaldehyde adhesive and continually improved to decrease formaldehyde emissions.

Phenol-formaldehyde Resin For Producing Particle Board

1. Bonding Strength: Phenol-formaldehyde Resin Powder provides excellent bonding strength, resulting in particleboard with high resistance to bending and tensile forces.

2. Durability and Stability: Due to its strong adhesive properties, particleboard is typically very durable and stable, resisting deformation or cracking.

3. Water Resistance: Particleboard manufactured with phenol-formaldehyde adhesive usually exhibits some level of water resistance, allowing it to maintain performance in humid environments.

4.Low formaldehyde emission: particle board phenol formaldehyde glue is a special type of glue with chemical composition and reaction mechanisms that result in lower formaldehyde emissions after curing. Phenol and formaldehyde in the adhesive react to form stable compounds during the curing process, reducing the release of unreacted formaldehyde. Also, strict quality control during the production of phenol-formaldehyde adhesive can ensure that the adhesive's composition and performance meet specified standards, thereby reducing uncontrolled formaldehyde emissions.

Phenol-formaldehyde resin For particle boards due to its various advantages. Here are some of the key benefits of using phenol-formaldehyde resin in particle boards:

Durability: Phenol-formaldehyde resin enhances the strength and durability of particle boards. It forms a strong bond between wood particles, resulting in a sturdy and long-lasting material.

Water resistance: Phenol-formaldehyde resin has excellent water resistance properties. This makes particle boards made with this resin suitable for applications where moisture exposure is expected, such as in kitchens and bathrooms.

Heat resistance: Phenol-formaldehyde resin exhibits high heat resistance, making it ideal for use in applications where particle boards may be exposed to high temperatures, such as in furniture near heat sources.

Chemical resistance: Particle boards made with phenol-formaldehyde resin are resistant to various chemicals, including solvents and acids. This makes them suitable for use in laboratories, industrial settings, and other environments where exposure to chemicals is a concern.

Dimensional stability: Phenol-formaldehyde resin helps to improve the dimensional stability of particle boards. This means that the boards are less likely to expand or contract due to changes in humidity or temperature, resulting in a more reliable and consistent material.

Fire resistance: Phenol-formaldehyde resin offers good fire resistance properties. It can help to slow down the spread of flames and reduce the release of toxic gases when particle boards are exposed to fire.

Overall, the use of phenol-formaldehyde resin in particle boards enhances their strength, durability, water resistance, heat resistance, chemical resistance, dimensional stability, and fire resistance. These advantages make phenol-formaldehyde resin a popular choice in the production of particle boards for various applications.