Phenol-formaldehyde Resin For Producing MDF

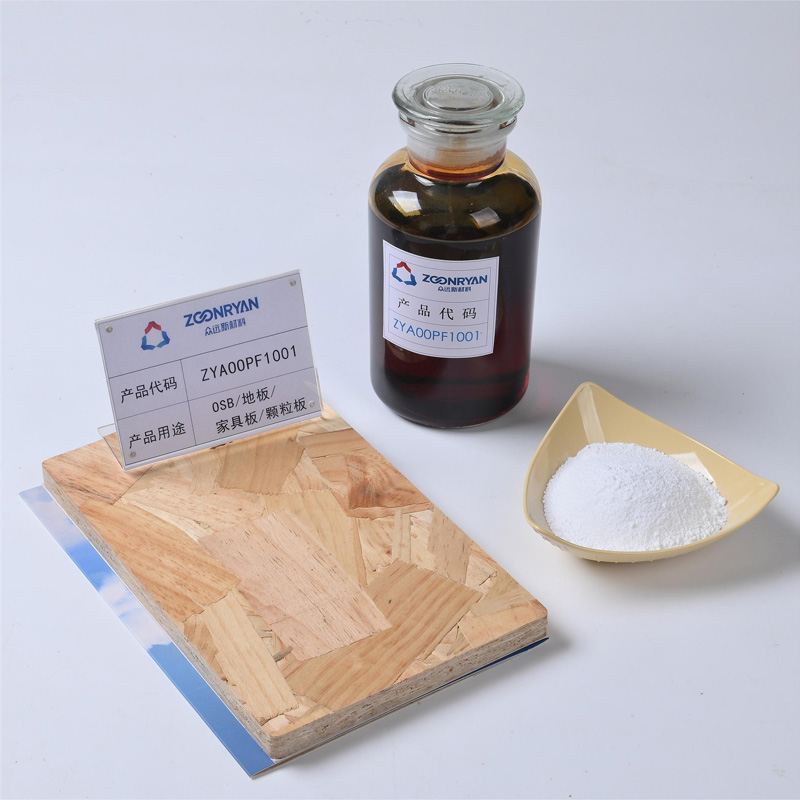

Phenol-formaldehyde adhesive is commonly used in the manufacturing of Medium Density Fiberboard (MDF). Copare to Urea-Formaldehyde Resin Powder and Melamine Formaldehyde Resin Powder, Phenol-formaldehyde adhesive in the manufacturing of MDF boards typically has low formaldehyde emission levels.

Phenol-formaldehyde Resin For Producing MDF

Phenol-formaldehyde adhesive is commonly used in the manufacturing of Medium Density Fiberboard (MDF), and it has the following advantages:

1. Strength and Stability: Phenol-formaldehyde adhesive in MDF provides high bonding strength, making MDF boards more durable and stable.

2. Wear Resistance: Using phenol-formaldehyde adhesive in MDF manufacturing process increases the board's wear resistance, making it suitable for furniture production and other applications.

3. Waterproofing: Phenol-formaldehyde adhesive can impart some degree of waterproofing to MDF boards, which is useful in applications in moist environments.

4. High Temperature Resistance: Phenol-formaldehyde adhesive exhibits good tolerance to high temperatures, making it suitable for some high-temperature applications.

5. Cost-Effectiveness: The production cost of phenol-formaldehyde adhesive is relatively low, which helps reduce the manufacturing cost of MDF boards.

6. Low formaldehyde emission levels: Phenol-formaldehyde adhesive in the manufacturing of MDF boards typically has low formaldehyde emission levels. This is because the chemical properties of phenol-formaldehyde adhesive result in relatively low formaldehyde emissions after curing.

Phenol formaldehyde adhesive is a type of adhesive commonly used for bonding Medium Density Fiberboard (MDF). It has several key features, including high strength and durability, resistance to moisture and heat, and excellent bonding properties.