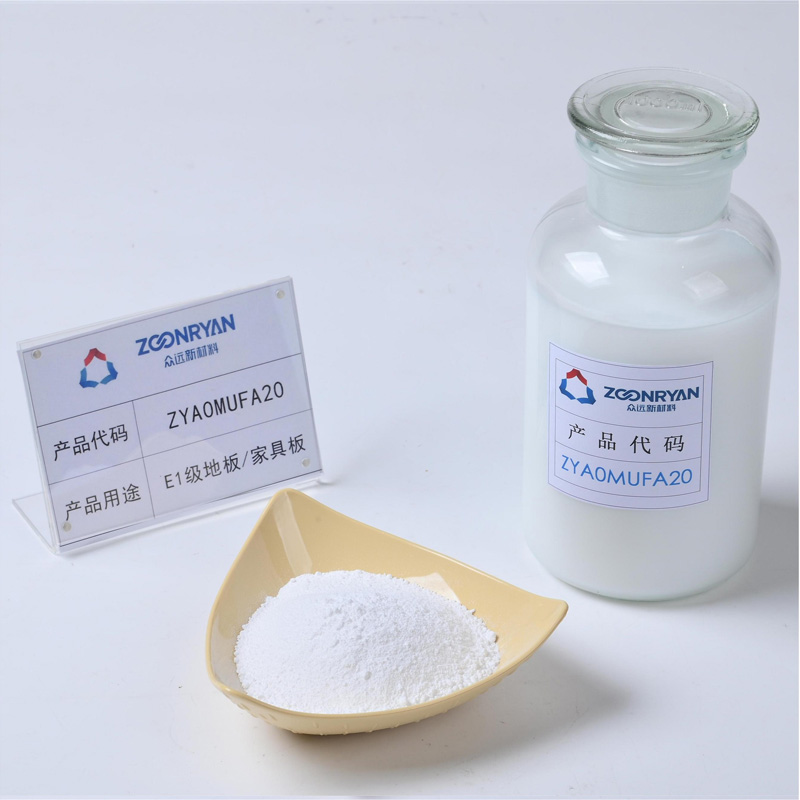

Melamine Formaldehyde Resin Powder Purity 98%

Melamine Formaldehyde Resin Powder Suitable for veneers used in fine wood boards, plywood, ecological boards, and flooring substrates with Class I requirements for immersion peel performance.

Melamine Formaldehyde Resin Powder

ZYA0MUFA11 is a thermosetting melamine-modified resin adhesive developed by Shandong Zoonryan New Materials Co., Ltd. The Melamine Formaldehyde Resin meets the Class I bonding strength and Class I immersion peel performance requirements according to national standards.

This adhesive is made from melamine, urea, and formaldehyde, and it has been modified to have extremely low free formaldehyde content while still maintaining considerable bonding strength and excellent water resistance.

Testing of the resin parameters reveals that the free formaldehyde content is ≤0.03%. Plywood produced with this adhesive meets the strength and immersion peel performance requirements of national Class I boards.

The formaldehyde emission from plywood produced with this adhesive is extremely low, ≤0.05mg/m³, meeting E0 level standard requirements.

Test Report

Number:XX2023042422

Sample Name | MIP Faced Plywood | Sample Grade | Qualified | ||||

Qualities | 500mm*500mm for two | Specifications | 1220*2440*18 | ||||

Production date | 202/06/ 28 | Test Date | 2023 / 0 7 / 12 | ||||

Inspection | GB/T 17657 -2013 | ||||||

Determination | GB/T 39600 -2021 GB/T 34722 -2017 | ||||||

No. | Items | Technical requirements | Test Result | Judgment | |||

1 | Formaldehyde release | Enf ≤0.025 | 0.017 | Qualified | |||

2 | Moisture | 6.0%~16.0% | 6.6% | Qualified | |||

3 |

Impregnation delamination |

/ |

No De lamination |

Qualified | |||

4 | Lateral static bending strength | Average ≥15.0MPa Lowest ≥12.0MPa | Average/24.1MPa Lowest/15.6MPa |

Qualified | |||

5 | Bonding Strength | ≥0.60MPa | 1.09MPa | Qualified | |||

6 | Surface crack resistance | Above 4th level | 5 l e v e l | Qualified | |||

Melamine Formaldehyde Resin Powder with a purity of 98% offers several advantages in various applications. Here are some of the key benefits:

High Strength and Durability: Melamine Polymer 98% purity has excellent mechanical properties, providing high strength and durability to the end product. It enhances the overall performance and lifespan of the materials it is used in.

Heat Resistance: This resin powder exhibits excellent heat resistance, making it suitable for applications where high temperatures are involved. It can withstand temperatures up to 120°C without compromising its structural integrity.

Chemical Resistance: Melamine Formaldehyde Resin Powder Purity 98% offers good resistance to a wide range of chemicals, including acids, alkalis, and solvents. This makes it ideal for use in environments where exposure to various chemicals is expected.

Water Resistance: The resin powder has excellent water resistance properties, making it suitable for applications that require products to withstand moisture or humid conditions without degradation.

Surface Hardness: When cured, melamine formaldehyde resin forms a hard and smooth surface, enhancing the overall appearance and providing resistance to scratches and abrasion.

Flame Retardancy: Melamine Formaldehyde Resin Powder Purity 98% is inherently flame retardant, making it suitable for applications where fire safety is a concern.

Versatility: MF Resin Powder Purity 98% can be used in a wide range of applications, including laminates, coatings, adhesives, molded products, and more. Its versatility allows it to be tailored to specific requirements and manufacturing processes.

It is important to note that the advantages may vary depending on the specific application and the quality of the resin powder used.