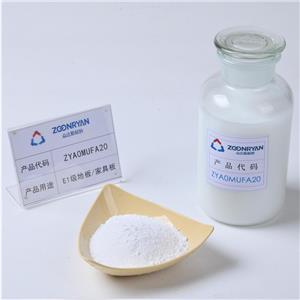

Melamine Formaldehyde Resin For Producing OSB

Direct involvement with OSB factories gives us a unique understanding of the industry's needs and challenges, allowing us to tailor our Melamine Formaldehyde Resin to better suit the specific requirements of OSB production.

Melamine Formaldehyde Resin For Producing OSB

Using Melamine Formaldehyde Resin (MFR) in the production of Oriented Strand Board (OSB) not only enhances its durability and moisture resistance but also brings additional benefits:

1. Increased Weather Resistance: MFR contributes to better weather resistance, making Oriented Stand Board suitable for exterior applications where exposure to the elements is a factor.

2. Improved Thermal Stability: MFR imparts greater thermal stability to Oriented Stand Board , allowing it to withstand higher temperatures without degrading, which is crucial for certain construction and industrial applications.

3. Enhanced Surface Finish: Oriented Stand Board made with MFR can have a smoother and more visually appealing surface, beneficial for applications where the aesthetic is important, such as in furniture or interior design.

4. Lower Formaldehyde Emissions: MFR can be formulated to release lower levels of formaldehyde, making OSB more environmentally friendly and safer for indoor use, an important consideration for green building certifications.

5. Greater Versatility: The improved properties of Oriented Stand Board made with MFR, such as strength and moisture resistance, increase its versatility, making it suitable for a wider range of applications, including flooring, wall sheathing, and roofing.

6. Cost-Effectiveness: Despite the enhanced properties, MFR can be a cost-effective option, providing a balance between performance and expense, which is crucial in competitive construction and manufacturing markets.

These advantages make MFR a valuable choice for the production of OSB, catering to both functional and environmental requirements.

Water resistance: Melamine urea formaldehyde resins can be used to make water-resistant OSB.

Moisture resistance: Amino resins can make panels moisture-resistant for exterior use.

Cost: Melamine formaldehyde resins are cost effective but lack acid stability.

Economics: MDI resins can be more economical than melamine-urea-phenol-formaldehyde (MUPF) resins.