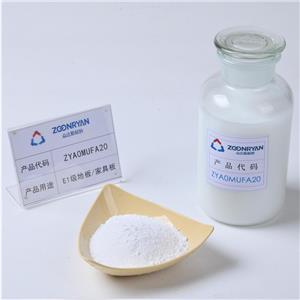

Melamine Formaldehyde Resin For Producing Manufactured Wood

Melamine Formaldehyde Resin, used in the production of engineered wood, is ideal for veneers applied to high-quality wood boards, plywood, eco-friendly boards, and base layers for flooring. It meets Class I standards for immersion peel performance, making it a suitable adhesive for these applications.

The advantages of using Melamine Formaldehyde Resin For Producing Manufactured Wood

Using Melamine Formaldehyde Resin (MFR) for producing Manufactured Wood offers several advantages:

1. Improved Durability: Melamine Formaldehyde Resin enhances the durability of particle boards, making them more resistant to wear and tear.

2. **Enhanced Moisture Resistance**: Manufactured Wood made with Melamine Formaldehyde Resin are more resistant to moisture and humidity, reducing the risk of swelling or deformation.

3. Increased Heat Resistance: Melamine Formaldehyde Resin increases the heat resistance of Manufactured Wood, making them suitable for applications where they may be exposed to higher temperatures.

4. Better Aesthetic Appeal: Melamine Formaldehyde Resin can give Manufactured Wood a smoother, more aesthetically pleasing finish, which is beneficial for furniture and interior design applications.

5. Improved Chemical Resistance: Boards made with Melamine Formaldehyde Resin are more resistant to chemicals, making them suitable for use in laboratories or industrial settings.

6.Enhanced Strength: The bond strength of Manufactured Wood is increased when Melamine Formaldehyde Resin is used, leading to stronger and more robust panels.

7. Low Formaldehyde Emission: Melamine Formaldehyde Resin can be formulated to have lower formaldehyde emissions compared to other resins, making it a more environmentally friendly and healthier choice for indoor applications.